Company Profile

Jingzhou Jinglong Aerospace Technology Co., Ltd

Professional auto parts manufacturer

Jingzhou Jinglong Aerospace Technology Co., Ltd. was established in 2005, located at No. 68 Xihu Avenue, Guanju Industrial Park, Shashi District, Jingzhou City, Hubei Province. The company is mainly engaged in the research and development of precision casting of aluminum alloys, precision machining, and laser welding, as well as product design and manufacturing. It has strong capabilities in precision casting and precision machining, with main products covering fields such as aviation, aerospace, ships, electronics, weapons, satellites, and automotive parts. It is recognized as a demonstration enterprise for intellectual property in Hubei Province and a national high-tech enterprise.

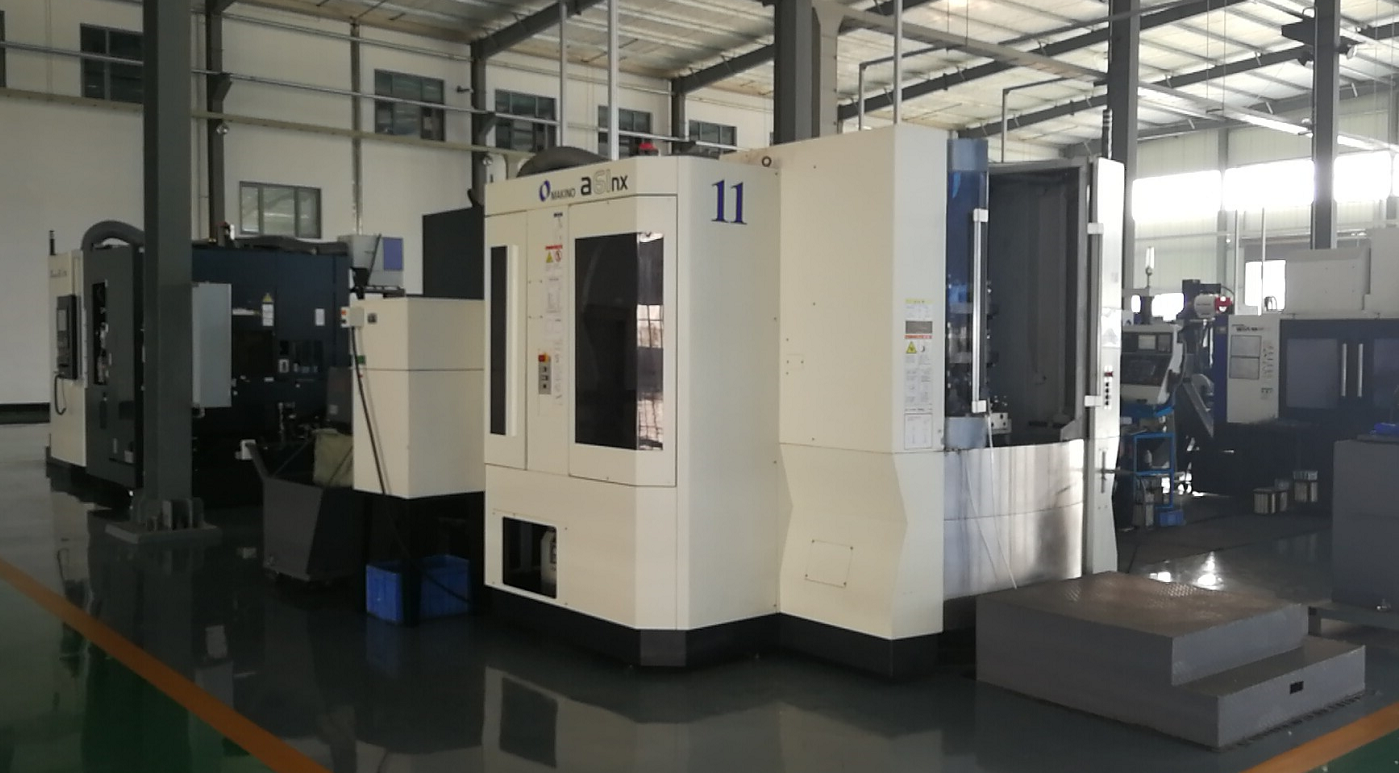

The company has two production sites. The new site, covering an area of 50 acres, focuses on non-ferrous metal products, while the old site, covering 158 acres, mainly produces ferrous metal products and TPV products. Currently, the factory area is 56,000 square meters, with hundreds of high-tech equipment valued at 150 million yuan, and a workforce of 500 employees.

The company currently has more than 40 professional technical personnel, including 2 with senior titles, 6 with intermediate titles, 3 with master's degrees, and 28 with bachelor's degrees. The main project management personnel come from large state-owned enterprises such as AVIC, CASIC, and CSIC, and are top figures in the domestic aluminum alloy casting and titanium alloy laser welding industries. The technical team includes national craftsmen who enjoy State Council subsidies, as well as senior engineers who have won two first prizes and two third prizes for scientific progress from CSIC, and a national excellent quality management group award. Under the leadership of the chief engineer, the company has formed a first-class professional technical team in the country with a sound system, mature mechanism, and strong innovation and research and development advantages and competitiveness. The high-strength, high-toughness aluminum alloy materials used, combined with unique special casting processes that break traditional casting methods, have achieved or even exceeded tactical performance indicators in terms of material properties, forming accuracy, and application performance, especially in mechanical properties and tactical indicators, leading the domestic market.

The company has established research and production joint ventures with several aerospace research institutes and has actively carried out industry-university-research cooperation with universities such as Northwestern Polytechnical University, Shanghai Jiao Tong University, and Harbin Institute of Technology, establishing a long-term cooperation mechanism in the field of materials science, cultivating a group of high-tech professionals for the research and innovation of new materials and new technologies.

Real Scene Display

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text